Blog #1

- Changyu Lee

- Sep 9, 2023

- 5 min read

Structure monitoring is very important, and current methods sometimes fall short. Bolt monitoring can be difficult to successfully do via visual inspection, and failing to properly inspect and maintaining structures can have dire consequences, including loss of life. Bolt monitoring that is done through visual inspection is not a preferred strategy because it can usually only tell when a bolt is extremely loose as opposed to when a bolt is somewhat torqued [1]. Furthermore, equipment that is usually accessible for smaller bolts, such as torque wrenches, isn’t widely available for larger commercial bolts. Instead, the equipment that is used on these larger bolts is extremely expensive and generally static while in use [2-4].

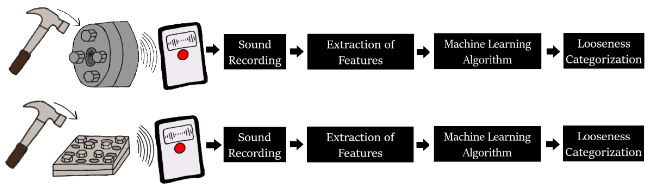

Current tools used for gauging large bolt looseness on commercial structures, such as large flanges, can be very expensive and limited in the number of structures they inspect, requiring semi-permanent installation to constantly monitor one therein [6]. The solution we’re looking for should be low-cost and have the ability to monitor a fair number of larger commercial bolts. This solution should help monitor bolts faster and more efficiently, thus helping improve the efficiency of maintenance therein. Given that any solution herein will be required not to be permanently affixed to the bolts nor their respective structure, it is expected that the proposed solution will use either vibrational analysis or signal processing to determine the tightness of the bolts [5,7-9]. Data from bolts at different torques would likely be analyzed within some software, which may include machine learning or other similar systems, either to categorize the different levels of tightness or see if a bolt is at a target torque.

Ultimately, the goal would be to develop a consistent method by which to monitor large bolts while overcoming obstacles often related to visual inspection. We have two academic semesters to work on this project, so in terms of end-of-year deliverables, a solution that can examine large bolts, process data associated with the bolt, and finally accurately categorize the data is expected.

While supervised learning algorithms have been demonstrated to be successful in bolt monitoring, unsupervised learning has not. This means that for the time being, we need to work with what we know. This would entail employing a supervised learning algorithm, and thereby making any device we make that uses the percussion method of bolt monitoring, in need of calibration before use. Any structure the device is used on will require a data baseline. Theoretically, if a company has a lot of similar structures in the same noise environment, calibrating for one should make the device applicable to all of them. We also anticipate that there will be a significant amount of code involved and it’s possible that we won’t be able to install the bolt sorting program on the portable device itself. This implies that the data may be uploaded to a different application. If this is the case, then calibration and monitoring using the device will take longer.

On top of everything else, there’s the fact that features will have to automatically be extracted if we want this to be a tool that doesn’t require much training. Unfortunately, most percussion monitoring up to this point used manual feature selection. As such, we had to validate for ourselves that this could be done, so a lot of tinkering with audio processing tools was done in MATLAB. Up to this point, the experience within the group had been limited to picking features out manually by looking at pictograms of the sound data. At first, automatic feature extraction was tested to see if machine learning algorithms could differentiate between levels of torque, and it was not successful. This issue almost made us switch to a different project. However, instead of gauging levels of torque, we found that algorithms were able to tell, a majority of the time, whether a bolt was tightened to a target torque or not. This immediately made the project viable again.

The confusion chart above shows how this sort of categorization is viable. It was achieved using a neural network, and it differentiated between a targeted bolt torque of 210 ft-lb on a 16” flange and looser bolt torques. While accurately identifying 475 pieces of loose data and incorrectly identifying 260 may initially seem bad, it actually works very well for our purposes. Each piece of data is an individual tap on a bolt, and it is expected that anybody who uses our solution will tap on the target bolt a number of times before classifying it. As long as a good majority of the taps are accurately classified, we can have our solution output the correct outcome. Visualize it like this:

Albeit instead of tapping just five times, people who use our solution might be tapping more. We also have time to refine our methods of audio processing in order to increase the accuracy therein. At minimum, we understand it to be a viable option for our purposes.

Overall, we’re looking forward to how this project develops. Given the importance of bolt monitoring as well as the potential for this solution, we’re excited to develop this idea into something more concrete. It’ll take a while, given that specifications and constraints need to be nailed down first, but ultimately this project seems very promising!

References:

[1] A. Duzgun, J. A. Rice, J. R. Martinez, and I. R. Lasa, “Comparison of Visual Inspection and Structural-Health Monitoring As Bridge Condition Assessment Methods,” Journal of Performance of Constructed Facilities, vol. 30, no. 3, Jun. 2015. doi: https://doi.org/10.1061/(ASCE)CF.1943-5509.0000802

[2] ABQIndustrial, “Mark-10 MTT03C-100 hand-held cap torque meter cap-TT03-100, 100 lbf-in capacity,” ABQIndustrial Inspecting, Precision Measuring & Test Instruments Since 1996, https://www.abqindustrial.net/store/mark-10-mtt03c-100-hand-held-cap-torque-meter-cap-tt03-100-100-lbf-in-capacity-p-807-op-1306_4671.html?gad=1&gclid=CjwKCAjw6eWnBhAKEiwADpnw9heBXm_PN3KCr8GHo1MGoTzGjjNXTINxTw26eTqn_a_wPSu4qVcN9xoCrnAQAvD_BwE (accessed Sep. 7, 2023).

[3] “ATG / BTG Torque Gauge Archives,” Tohnichi America, https://www.tohnichi.com/product-category/torque-measuring-equipment/torque-gauge/atg-btg-torque-gauge/ (accessed Sep. 7, 2023).

[4] Chen, J., Chen, Z., Zhu, W. and Song, G., (2023). Underwater bolted flange looseness detection using percussion-induced sound and Feature-reduced Multi-ROCKET model. Structural Health Monitoring, p.14759217231153991.

[5] Kong, Q., Zhu, J., Ho, S. C., & Song, G. (2018). Tapping and listening: A new approach to bolt looseness monitoring. Smart Materials and Structures, 27(7), 1–6. https://doi.org/10.1088/1361-665x/aac962

[6] “OEM flange-to-flange reaction torque sensor,” Futek, https://www.futek.com/store/torque-sensors/reaction-torque-sensor/oem-flange-to-flange-reaction-TFF350 (accessed Sep. 7, 2023).

[7] Wang, F., & Song, G. (2021). A novel percussion-based method for multi-bolt looseness detection using one-dimensional memory augmented convolutional long short-term memory networks. Mechanical Systems and Signal Processing, 161, 107955. https://doi.org/10.1016/j.ymssp.2021.107955

[8] Wang, F., Song, G., & Mo, Y. L. (2020). Shear loading detection of through bolts in bridge structures using a percussion‐based one‐dimensional memory‐augmented convolutional Neural Network. Computer-Aided Civil and Infrastructure Engineering, 36(3), 289–301. https://doi.org/10.1111/mice.12602

[9] Zhou, Y., Wang, S., Zhou, M., Chen, H., Yuan, C., & Kong, Q. (2021). Percussion‐based Bolt looseness identification using vibration‐guided sound reconstruction. Structural Control and Health Monitoring, 29(2). https://doi.org/10.1002/stc.2876

Comments